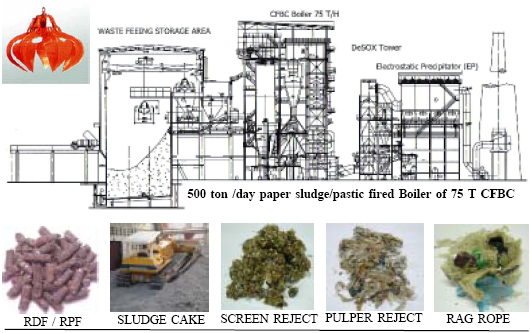

| PAPER SLUDGE/PLASTIC WASTE FIRING CFBC BOILER |

We have successfully installed boiler using paper sludge/plastic waste 500 ton a day at Tianjin City of China

in 2008. This papermill has 500 tons of waste materials from their process. 200 ton of paper sludge with

almost 74% water content, and 300 tons of waste plastic of mixture of screen reject, pulper reject and rag

rope which has a content of steel wired that must be removed first and water content is about 59%. In order

to reach required heating value and water average water content, coal of about 154 ton/day is mixed to have

the average water content of 51.36%. With this water content, heating value will become 2,113 Kcal/Kg.

|

|

| Hamada Boiler introduces plastic

waste firing FBC boiler for papermill

in Thailand |

BANGKOK: In the year 2008,

Hamada Boiler went into a contract

with HIANGSENG PAPERMILL

of Thailand for building 25 ton/H

waste plastic firing BFBC boiler in

order to make use of huge quantity

of waste plastic coming out from

the recycling process of paper.

Boiler pressure vessel picture

shown at the right side is the model

DF25, bubbling bed FBC for 25

ton/H capacity. In addition to the

main screw feeder for the plastic

waste, it equip with spare feeder for coal fuel so that coal can

be mixed when the plastic waste contains excessive water in

order to maintain the furnace temperature at about 850 oC

at all time.

Right above picture is Mr. Hans Muhry, company's executive

engineer, inspecting the huge quantity of plastic waste

produced everyday from the process line. This is a common

problem to all papermills who uses recycled paper containing

plastics. Paper Factories who have similar plastic waste may

contact us for this latest technology. |

|

|

|

This paper factory produces paper

sludge of almost 200 ton/day with

65-74 % water content and directly

used to the boiler without drying but

with coal mixture. If this sludge will

be dried, coal consumption will be

reduced accordingly.500 T per day waste firing capacity/

75 ton CFBC 39 bar 450 oC

15 MW turbine power plant x 2

Tianjin, near Beijin China

China do not have the restriction

of transport of plastic waste and

this plant uses raw and wet

plastice waste as fuel. |

This chart is the data of daily disposal of plastic waste from the waste

paper processing for carton box paper of one of the biggest factory in

Taiwan,. There are 3 kinds of wastenamely pulper reject screen reject

and Rage rope. Rage rope contains steel wires which must be

removed by magnetic steel separator. In Taiwan, government restrict

the transport of this kind of plastic waste if it is considered as industrial

waste. Therefore, this must be processed first to become RPF. The |

|

| PULVERIZED COAL

BURNER WITH

ASPHALT MIXING PLANT |

Most of Asphalt Mixing Plants by average consumes

600 Liters of oil per hour for the production

of 50 tons of asphalt mix per hour. Do you

want to cut this oil cost? YES, YOU CAN. We

can change your oil burner with very unique coal

burner with specially designed COMBUSTER.

Do you worry about the ash from coal? No problem.

In Indonesia, government issued certificate

that the ash from coal mixed to the asphalt can

be used as FILLER and the result is better than

the oil. SAVING CALCULATION: This is a

direct fire system.

Saving is

so simple.

How much are

you using for

your operation?

Let's say 500

liters of bunker

oil or Diesel Oil?

Your saving will

be 80% of what

you are paying for at present. |

|

|

We will bring revolution to all Asphalt Mixing Plants. We will

replace your oil burner with pulverized coal burner and the ash

from the coal will act as FILLER to make your asphalt mix better

quality. This matter has been proven in many asphalt mixing

plant in Indonesia with government certificates. |

|

|

| PULVERIZED COAL BURNERN

FOR BOILER APPLICATION |

Huge power plant boilers uses Pulverized

Coal Combustion technology.

We use the same principle but

do it on small scale application using

pulverizer/

burner

in one

packaged

unit. The

said coal

pulverizer/

burner can

be used in

many types of heating equipments

as long as the ash can find the way

to be disposed, or the products to

be heated could accept ash, like in

the case of Asphalt Mixing Plant.

Picture on the right shows a successfulapplication of a coal burner

with the rotating combuster installed

in front of the smoke tube boiler. |

|

|