| 75 ton 60 bar 450 oC

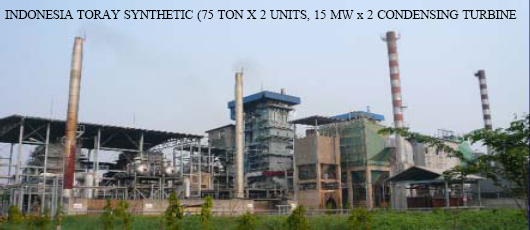

HIGH PRESSURE CFBC FOR

POWER PLANT BOILER |

|

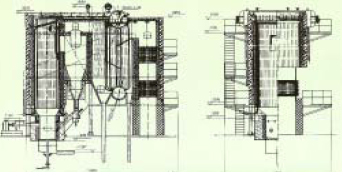

HAMADA CFBC BOILER OF 75 TON Membrane wall design, which permits standard insulation and

lagging greatly reducing radiation losses as compared to the conventional tube arrangement with thick

refractory |

CO-GENERATION PROJECT:

Utmost saving can be obtained

when you generate electricity by

high pressure steam and use extraction

steam or exhaust steam for

your processing need. |

LOW PRESSURE/ BI-DRUM CFBC BOILER

For lower pressure requirement below 25 bar, Bi-Drum design will

be used instead of single drum. Hamada Boiler expanded its range

of product to the lower pressure CFBC with this design to answer to

the need of below 35 ton capacity. |

|

|

|

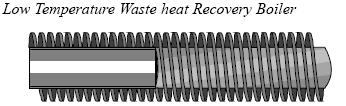

The Latest Heat Pipe Technology |

| THERMAL VACUUM

TUBE WASTE HEAT

RECOVERY BOILER |

|

This technology is really a revolutionary

for the low temperature flue

gas of 200-400 oC. Before, waste

heat recovery boiler uses ordinary

boiler tube and low temperature flue

gas passes through the boiler, thus

needing huge area of heating surface

for the low temperature gas and

causing a serious problem of carbon

accumulation inside the boiler that

will automatically increase the air resistance

which might cause damage

to the diesel generator engine. Now,

with this new technology, flue gas |

PLEASE VISIT OUR WEB SITE:

http://www.hamadaboiler.com

FOR MORE DETAIL INFORMAITON, EMAIL TO OUR

OFFICE: sales@hamadaboiler.com

Or send your question directly to our Chairman and CEO

Mr. Kazuhiro Hamada (+62 8161674489 roaming)

email: kazuhiro@hamadaboiler.com

MSN: hamadalo88@hotmail.com

Skype Name: hamadalo88 |

|

|