| Coal Fired Boiler |

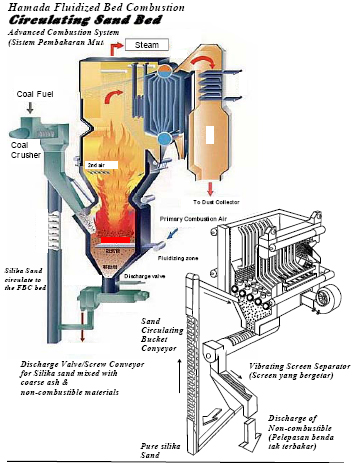

Fluidized Bed Combustion (FBC)

technology has seen rapid expansion

in the last 10 years and now

represents a significant sector of

the market for coal fired boilers.

Reasons for this success include

low acid gas emissions and greatly

enhanced fuel flexibility. Principles

of Fluidized Beds are

when solid particles

can be moved by

a fast stream of

air or other gas,

for example when

pressurized air or other

gas is admitted below a column of

solid particles the particles are lifted

and separated by the passage of

the gas until, as the rate of gas flow

is increased, they behave as a liquid

with vigorous movement and

mixing.

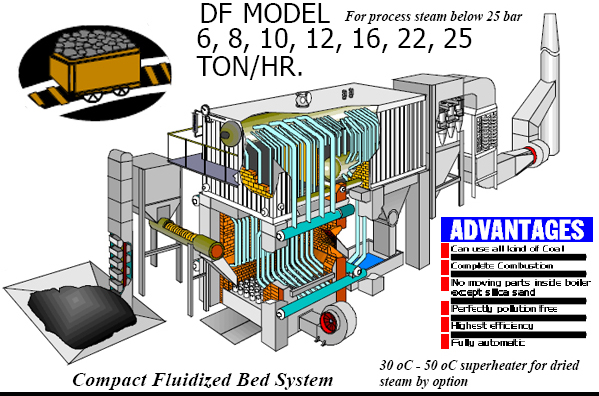

Compare to conventional boiler

design, FBC boiler allows fuel to

stay longer in the combustion

chamber thus providing sufficient

time to have enough contact with

air. Also, due to the in-bed turbulence

and the scouring action of the

bed materials on the heat transfer

surface, the fireside heat transfer

coefficient can be about 3 times than that of boilers using conventional

firing system. Its combustion

efficiency is such that it

can burn virtually every last

scrap of energy in the fuel.

The very low content of unburned

carbon in the disposed

ash further attests to its high

combustion efficiency as

high as 99%. The

temperature in the

FBC area is kept

below the ash melting

point at 850 - 950

oC. This low combustion

temperature prevents

fusion

of

ash and

the formation

of

clinkers in the

furnace thereby

minimizing the bad effects

of fouling and erosion of

heat surface. This is especially

important for fuels with very high

ash content like low-grade coal

and low ash fusion point. |

|

Top and 2nd largest

papermill in Taiwan are using

Hamada FBC Coal Boiler |

TAIPEI: Taiwan has almost 36 Boiler Manufacturing comapnies

locally. But no one until now manufactures fluidized bed boiler. Due

to the Taiwan government strict control on environment which set the

limit of NOx as low asJapan level,chain grate boiler can not meet the

requirement any more. This is the main reason that the top and 2nd

largest papermill of Taiwan selected Hamada FBC Boiler. FBC

boiler can easily pass the government rule on NOx because of low

combustion temperature.

Cheng Loong PaperMill (Zhupei Factory and Tayuan Factory) and

Yong Fong Yi (YFY-Yangmei Factory, YFY-Chingsui factory, and

Union paper-Douryu factory) are using Hamada Boilers . |

|

|

|

400kw RICE HUSK POWER PLANT

Actual unit operating in Indonesia since 2007

in Wonosobo, Central Jawa. Bernadi Rahaju

(Director Utama) of PT Dieng Jaya/ PT National

Champignon said this is a wonderful

set up to produce small scale electricity without

using steam boiler.

And their company are

going to place an repeat

order of 800 KW within

this year. Some people

worries about tar from

the combustion of rice

husk/wood. But we

have completely soved this tar problem by

adding tar treatment system together with

the existing environmental equipment.

|

|

venturi scrubbers and cooling towers. Water is employed as

the cooling and scrubbing media. Waste heat

recovery is also available for domestic and

industrial heating purposes. The cooled and

cleaned gas is pumped through a Hi-volt electrostatic

participator (optional) to remove the

remaining tar and particulate before being

used in the gas engines.

Gas Engines and Generators

The combustible gas is directly used in reciprocating

gas engines to power generators

to produce electrical energy. The system is

much compact and simple. In addition, it can

also be used for other heating or direct combustion

applications. One may ask that the

biomass or producer gas can be burned in

boilers to produce steam for piston engines

or turbines, however these operate at a relatively

low efficiency and require large steam

plant and huge initial investment. The gas

engines are professionally retrofitted diesel

engines which are simple in operation reliable.

Relevant technical personnel are

readily a vailable, even in rural regions of

developing countries. |

|

| Internal Travelling Chain Stroker Fire Tube Boiler of 10 ton Capacity |

Biomass Gasification Most of us believe that wood (a kind of biomass) burns. However,

if looking closely at the fireplace, the pyrolysing wood does

not burn at the wood surface. The wood evolves a combustible

gas, which burns whenever it encounters oxygen in the air. In

simple term, Biomass Gasification is the breaking down of biomass

material in the absence of oxygen to produce volatile vapor

as a kind of combustible gas. The volatile vapor, usually known

as Producer Gas, contains H2, CH4, CO as the sources of energy

and typically CO2 and N2 as the unwanted diluents. The

biomass is fed into the Gasifier and fluidized to heat up to about

800 oC to generate Producer Gas which needs to be cleaned

and cooled down prior to being used in gas engines.

Producer Gas Treatment

The Producer Gas from the gasifier is very hot at about 750 oC.

It passes through a cyclone separator to remove the coarse particulates

and then passes through a series of |

| Fuel feeding equipment |

Hamada Boiler also offer various kind of solid fuel feeding

system. Also available pelletizing machine/ crushing machine to

pre-process various kind of fuels for the best shape to feed into

the boiler. 2 Picture from the left shows shaftless screw

conveyor which is used for plastic waste boiler and citiwaste

feeding. Picture right is the SATRINDO shredder for shredding

plastic botols, containers, used tired etc. Waste tires can be shredded by this machine and pass through

the magnetic steel wire removing equipment

before feeding into the boiler. Our boiler

operating in Taiwan are using about 20 %

used tires without emitting black smoke, but

the flying particles from the tire fuel need bag

filter and DeSOx tower. |

|

|