| Philippine San Miguel Corp. eyes on diversification in the Energy Sector |

MANILA: San Miguel Corp., Southeast

Asia's largest food and drink group, is diversifying further in the utility sector.

In December last year, San Miguel acquired the Government Service Insurance System's 27 percent stake in

power utility giant Manila Electric Co.

for around P30 Billion and has agreed

to buy up to 50.1 percent of giant oil

refiner Petron Corp. for P32.2 billion.

San Miguel, through unit San Miguel

Energy Corp., is expanding its investments in the power sector by joinning biddings for government owned assets. San Miguel Energy has submitted to the Power Sector Assets and liabilitys Management Corp. a letter of intent to

acquire the 620 megawatt combinedcycle power plant facilities in Limay, Batangas. |

SAN MIGUEL CORPORATION

AWARDS HAMADA GROUP THE

SUPPLY OF FLUIDIZED BED

BOILERS FOR ITS FOOD PROCESSING

AND BREWERY

PLANTS.

Manila: SMC awarded Hamada Group the

supply of biomass-wastes fired Fluidized Bed

Boilers for its Brewery in San Fernando,

Purefoods-Hormel in Cavite and Ginebra San

Miguel in Bacolod within the year. The boiler

system will be equipped with pollution control

equipment that is to comply with the R.A. 8749

otherwise known as the Philippine Clean Air

Act. SMC's plan also includes the brewery

plants in Polo, Cebu and Davao. In line with

its fuel-saving and diversification plan SMC

will go for indigenous renewable biomass

wastes fuel and may even consider the use of

coal over the long run. It was learned from

reliable sources that San Miguel Corp is interested

to purchase majority stake in one of the

biggest coal mining companies in Indonesia. |

|

| Demand of Biomass FBC Boiler is

increasing in Japan with Government

subsidy. |

TOKYO: In line with the worldwide

movement to reduce CO2, Japanese

government is now helping industries

by extending Financial assistance as

big aqs 30% on the investment of equipment

for utilization of biomass energy

to replace petroleum fuel. There are

many chicken paultry with 300,000

chicken and 10,000 chicken produce

as big as one ton of Chicken Manure

.so 300,000 chicken produce 30ton of

manure everyday (30% wet base).

Paultry is equipped dryer for the manure

before it is discharged and dried

up to 30% water content. For this size

of poultry, we will reccommend 3-4

ton steam boiler and to generate 100

KW by using the back pressure turbine

of SHINKO TURBINE WORKS of

Japan. Back pressure will be utilized

for Poultry in various sectors. |

|

|

| Pelletizing of Biomass FuelBoiler Illustrate at the right side (Model

SHL) can accommodate various kind

of biomass fuel without pelletizing. But

for Fluidizing Bed, those fuel with very low density and/or fiberous condition

fuel may be better to have it pelletized/

compressed like in this picture. Pelletizing

machine is available to fit various

condition of biomass. |

|

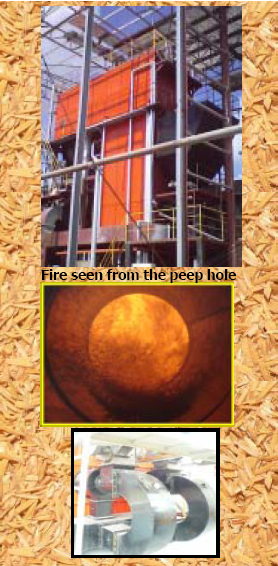

| Rice Husk Boiler |

|

HOCHIMIN CITY/VIETNAM: Cai

Lan Oils & Fats Industries Company

Ltd of Malaysia has several vegetable

oil refineries in Vietnam. Hamada Boiler

made its remark- able success to install

first in the history, 100% rice husk firing

boiler. What is remark- able is in the

design of combustion system, that uses

specially designed rice husk burner to spray the rice husk into the furnace of and almost 80% of ricehusk burns

in the air in suspension,

then the

rest of 20% will

fall onto the heavy duty chain stoker running slowly at hte

bottom of the furnace. This is a very

unique system of rice husk combustion

without necessity to make briquet of

rice husk like in the picture. For Chain

stoker system if burner is not used shall

have to use briquetted rice husk. In

Vietnam, rice husk will cost about Dong

500 per KG (price delivered by boat

along the river bank if your factory has

access to the river) that is about

US$0.0277 per KG($27 per ton). But

this price is a raw rice husk without

compressed or made into briquet. If

compressed, cost will become almost

double althoug transport cost will be

reduced. |

|