page 16

| HAMADA BOILER WEB CATALOGUE |

| Fbc 5 |

page 18

page 16 |

|

page 18 |

Fluidized Bed Combustion Technology(4) |

PRINCIPLE OF FLUIDIZATION |

Ash softening temperature is an important parameter. The fluidized bed must operate in a “Dry” condition since any stickiness has the potential to cause uncontrolled agglomeration and ultimately defluidization. Relatively few coals can produce sufficient stickiness below about 900 oC to upset fluidization, though coals which contain appreciable amounts of chlorine and/or alkali metals such as Na and K are known to give problems. |

|

ONLY FLUIDIZED BED SYSTEM CAN OPERATE JUST LIKE OIL/GAS BURNER (Turn-down ratio 1/4) |

|

Generation of heat can be adjusted freely up to the turn-down ratio of about 1/4 by controlling coal fuel feeding and forced fan damper openig to the minimum fluidizing velocity. At the minimum fluidizing velocity, sand bed is still fluidizing and continue to generate steam at 1/4 capacity. Between this range of evaporation, Fluidized Bed can react most likely to the Oil/Gas burner among any conventional coal firing system such as chain grate and/or underfeed stoker. |

|

NO LOSS OF REMAINING FUEL WHEN SHUT DOWN YOUR BOILER |

|

|

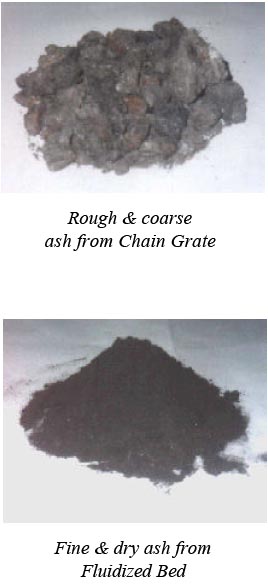

Not like with the other systems, you do not waste any remaining coal fuel when you want to stop the boiler. Remaining coal still inside the sand bed when you turn off the air supply to the bed shall have no more Oxygen supply and trapped inside the hot sand without wasting carbon for no use. For any other coal fire system like chain grate, all coal fuel already stay on top of the moving chain grate shall have to finish buring even the boiler stop operating and you do not want steam any more. Those loss will count greatly in a long time when comparing Fluidized Bed and Chain Grate. All ash will go out of Fluidizing Sand bed in a very dry condition under low temperature of about 900 oC. This condition of ash will never make problems of clinkering and never stick on the surface of boiler tubes. Therefore, soot blower is not needed for Fluidized Bed as mentioned previously. Only fine and dry ash are collected by the multicyclone system aftr the boiler and to be discharged through the rotary valve. Since the quality of ash coming out from Fluidized Bed is very fine and equal in its size, ash from the Fluidized Bed Boiler will find commercial value for fertilizer, mixing agent for cement moulded product, construction material, filler for road making etc. Ash from other coal firing system such as chain grate are very rough/coarse due to its high temperature above ash melting point, and can not find its commercial value. |

NO CLINKER, NO ASH FOULING/SLUGGING |

|

page 16 |

Download This |

page 18 |