75 TON 60 BAR 450oC

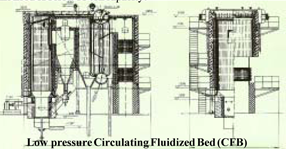

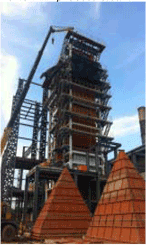

HIGH PRESSURE CFBC FOR POWER PLANT BOILER |

|

HAMADA CFBC BOILER OF 75 TON Membrane wall design, which permits standard insulation and lagging greatly reducing radiation losses as compared to the conventional tube arrangement with thick refractory.

|

|

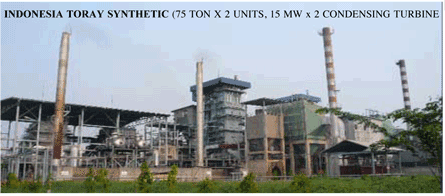

CO-GENERATION PROJECT: Utmost saving can be obtained when you generate electricity by high pressure steam and use ex- traction steam or exhaust steam for your processing need. |

LOW PRESSURE / BI-DRUM CFBC BOILER

|

|

For lower pressure requirement below 25 bar, Bi-Drum design will be used instead of single drum. Hamada Boiler expanded its range of product to the lower pressure CFBC with this design to answer to the need of below 35 ton capacity. |

|

| |

|

Co-Generation Project by Hamada Boiler

ASIA KRAFT PAPER (AKPC) OF BANGKOK INSTALL 9MW COAL FIRED POWER PLANT

Most effective and ultimate saving project by Back Pressured Turbine of 9MW with 75ton/H Process Steam |

BANGKOK; 6 years ago AKPC started to use Hamada FBC coal boiler for theor process steam re- quirements and in 2011, signed a contract with Hamada for building a co-generation coal power plant with 75 ton/H CFBC high opressure boiler of 9.8 MPa pressure with 540 oC suoperheated steam with 100% back pressure turbine of 9 MW. Back pressure steam of 10 bar will be fuolly utilized for the process of their papermill.

This is the sample of the most ulti- matesavingwayofsteamandpower genetation by coal. Among many factories not many company can adopt this similar style because they may not have this much of huge steam requirement of low pressure steam withy the balanced and stable load of electric power. |

|

|

| DOLE PHILIPPINES GOES TO BIOMASS MULTI-FUEL BOILER FOR GENERAL SANTOS PLANT |

GENERAL SANTOS; Pilippines One of the biggest Pineapple plan- tation and cannery DOLE PHILIP- PINES has started Biomsdd project for their process steam requirement by using Hamada Biomass Boiler of rice husk / cocoshell multi fuel system.It consist of two units of 18 ton capacity equipped with the spe- cially designed rice husk burner with the tavelling grate for cocoshell fir- ing. Installation work will start in April asnd will be completed by Au- gust this year. |

|

|

| FONTGINEBRA SAN MIGUEL BACOLOD DISTILLERY USES COAL FIRED FBC BOILER |

fontBacolod,Philippines: San Miguel Corp.,South east Asia's largest food and drink group, is diversifying further in the utility sector. First trial was done with its group, Bacolod DBI (Distilleria Bago Inc.) with16ton/H Hamada Fluidized bed Boiler to take care of its process steam requirement. Now that the substantial saving has been realized since one year of operation, it is possible to expand to other group factories and brewery this year.Ginebra is using the local coal of Semirara and PNOC.Philippine have several coal mining and quality of coal is very much accepted by Fluidized bed boiler and sulfur content of the coal is comparatively low as same level of that of Indonesian coal that no additional DeSOx tower is required to meet the local SO2 emission standard. |

Please visit our website: www.hamadaboiler.com

For more Detail Informatin, e-mail to our Office at: sales@hamadaboiler.com

or send your question directly to our chairman and CEO Mr. Kazuhiro Hamada (+63 920 9828 303 roaming)

email: hamadalo8@gmail.com

skype ID: hamadalo88 |

|

|