COAL FIRED BOILER

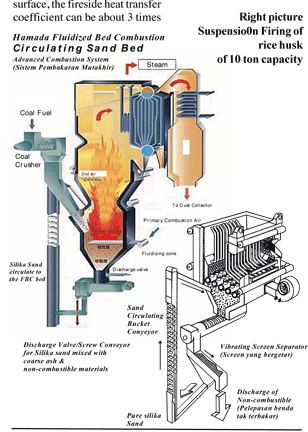

Fluidized Bed Combustion (FBC) technology has seen rapid expansion in the last 10 years and now represents a significant sector of the market for coal fired boilers. Reasons for this success include low acid gas emissions and greatly enhanced fuel flexibility. Principles of Fluidized Beds are when solid particles can be moved by a fast stream of air or other gas, for example when pressurized air or other gas is admitted below a column of solid particles the particles are lifted and separated by the passage of the gas until, as the rate of gas flow is increased,they behave as a liquid with vigorous movement and mixing.

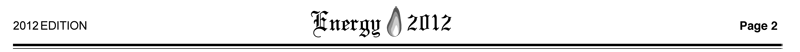

Compare to conventional boiler design, FBC boiler allows fuel to stay longer in the combustion chamber thus providing suffcient time to have enough contact with air. Also, due to the in-bed turbulence and the scouring action of the bed materials on the heat transfer surface, the fire side heat transfer coefficient can be about 3 times than that of boilers using conventional firing system. Its com- bustion efficiency is such that it can burn virtually every last scrapofenergyinthefuel.

The very low content of unburned carbon in the disposed ashfurther attests to its high combustion efficiency as high as 99%. The temperature in the FBC area is kept below the ash melting point at 850 - 950oC. This low combustion temperature prevents fusion of ash and the formation of clinkers in the furnace thereby minimiz- ing the bad effects of foulinganderosion of heat surface. This is especially important for fuels with very high ash content like low-grade coal and low ash fusion point. |

|

Top and 2nd Largest Papermill in taiwan are using Hamada FBC coal Boiler

TAIPEI: Taiwan has almost 36 Boiler Manufacturing comapnies locally. But no one until now manufactures fluidized bed boiler. Due to the Taiwan government strict control on environment which set the limit of NOx as low as Japan level,chain grate boiler can not meet the requirement any more. This is the main reason that the top and 2nd largest papermill of Taiwan selected Hamada FBC Boiler. FBC boiler can easily pass the government rule on NOx because of low combustion temperature.

Cheng Loong PaperMill (Zhupei Factory and Tayuan Factory) and Yong Fong Yi (YFY-Yangmei Factory, YFY-Chingsui factory, and Union paper-Douryu factory) are using Hamada Boilers .

|

|

|

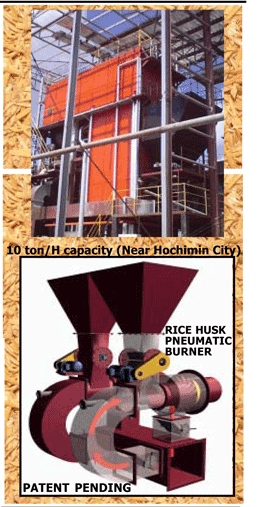

Rice Husk Boiler

HOCHIMIN CITY/VIETNAM: Cai Lan Oils & Fats Industries Company Ltd of Malaysia has several vegetable oil refineries in Vietnam. Hamada Boiler made its remarkable success to install first in the history, 100% rice husk firing boiler. What is remarkable is in the design of combustion system, that uses specially designed rice husk burner to spray the rice husk into the fur- nace of about 800 oC and almost 80% of rice husk burns in the air in suspen- sion, then the rest of 20% will fall onto the heavy duty chain stoker running slowly at hte bottom of the furnace. This is a very unique system of rice husk combustion without necessity to make briquet of rice husk like in the picture. For Chain stoker system if burner is not used shall have to use briquettedricehusk. In Vietnam, ricehusk will cost about Dong 500 per KG (price delivered by boat along the river bank if your factory has access to the river) that is about US$0.0277 per KG($27 per ton). But this price is a raw rice husk without compressed or made into briquet. If compressed, cost will become almost double althoug transport cost will be reduced. |

|

|

Hamada Boiler In Bangladesh

Energy Independence from now and beyond

Dhaka: Hamada Boiler, which is known to be the Fluidized Bed Boiler Specialist, has set its eyes into supporting the Bangladesh in its quest for energy independence. The opening ofi tsBangladesh operation is in response to the Bangladesh Government request, as stated in the Bangladesh Energy Plan 2012 Update, which called for the: development of the country indigenous energy resources and promotion of clean technologies to sustain efficient energy supply and demand chains that will eventually lead to increase self-reliance and provide the much-needed boost to the country's economic front. The more than 70% savings on energy/power cost from the use of coal, as opposed to the traditional energy/power sources, is expected to trigger an exodus of factories and small power plants shifting to coal in no time. Such trend is predicted to persistand stay over the long run as the price of oil is expected to continually increase in the world market and as gas and power shortages, as well, is expected to perennially negatively impact the do- mestic affairs.

With Hamada Boiler's state-of-the-art Coal- Fired Fluidized Bed Boiler Technology using locally produced high-grade coal, the Bangladesh Government's goal of 60 percent self-sufficiency level in 2020 will definitely be within reach- permanently changing the energy/power landscape of Bangladesh from now on and beyond.

|

|