THERMAL VACUUM TUBE

HEAT PIPE WASTE RECOVERY BOILER

(Application of Heat Pipe Waste Heat Boiler in Utilization of Waste Heat) |

|

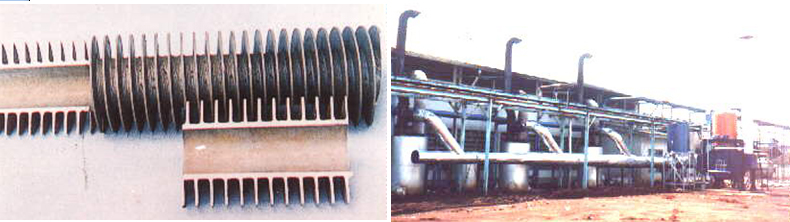

Left Image; Joint Venture of

Energy Research Institute of Zhejiang University, Hamada Boiler (Hangzhou) Factory |

|

Heat pipe is a kind of vacuum sealed pipe filled with high purity working fluid in free shape. It is divided into heating section, heat release section, and insulation section. The working fluid is heated and evaporated in heating section. Then heat is released at heat release section. And the fluid returns to the heating section to re-absorb the heat to transfer heat from one end to the other, so as to achieve the purpose of heat exchange |

|

Figure 1 Structure principle of heat pipe; Heat pipe waste heat boiler, with heat pipe as heat transfer component <gas - steam-based heat pipe heat exchanger>, has excellent characteristics beyond conventional limits, and plays an important role especially in waste heat recovery. |

Heating boiler, forging boiler, annealing boiler, heat treatment boiler, etc are producing equipment which is commonly used in enterprises which deal with iron and steel, non-ferrous metal processing, machinery manufacturing and so on. It is widely distributed all over the country in large quantity. Its annual energy consumption occupies a considerable proportion in the total energy consumption of all the enterprises. According to related statistics, the utilization rate of such boiler is usually only 20% ~ 30%. Heat taken by flue gas is 35% ~ 75%. This heat shall be recycled as much as possible. Boilers of glass industry consume much more energy, but their thermal efficiency is only about 20%. Heat loss mainly is heat dissipation of the boiler and flue gas exhaust. Therefore, obviously, it is practical to apply heat pipe waste heat boiler to produce steam for pre-heating of heavy oil system. |

1. Characteristics of heat pipe waste heat boiler

Compared with conventional waste heat boiler, heat pipe waste heat boiler has the following characteristics:

- Compact structure;

- Small thermal stress;

- Double isolation between water steam and heat source;

- Expanded heat transfer surface for flue gas side to improve the heat transfer process;

- Improved stability of water circulation and the condition of bubbling;

- Easy to clean the ash;

- Replaceable single heat pipe;

- Small resistance force of flue gas side.

|

| 2. Types of heat pipe waste heat boiler

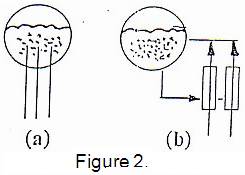

According to different layout of heat pipe heat section, heat pipe waste heat boiler, with heat pipe as heat transfer component, can be divided into two types: drum type and header type, shown in Figure 2 |

|

Figure 2 Two types of heat pipe waste heat boiler : Figure 2a is drum-type, with small size, light weight, and compact structure. Heat pipe is directly inserted into the drum; Figure 2b is header type. Heat pipe is inserted into the vertical casing pipes (header). Water is formed into steam water mixture inside the header and then goes into the drum. This type has more flexible arrangement; smaller number of holes opened on the drum, and is more convenient to be manufactured. These two types have their own different characteristics. The user can select according to specific circumstances. We have developed header type heat pipe waste heat boiler for glass industry with evaporation capacity of 5 ~ 10t/h. |

3. Parameters of heat pipe waste heat boiler

Parameters of heat pipe waste heat boiler include: evaporation, steam pressure and temperature. For boilers producing saturated steam, only steam pressure is needed.

The evaporation of heat pipe waste heat boiler we designed is 200kg/h ~ 10t/h. Common range of steam pressure is 0.3 ~ 1.0MPa.

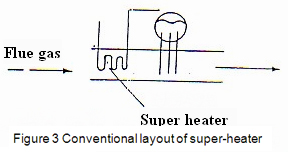

In order to further increase the steam pressure of waste heat boiler and make it suitable for higher flue gas temperature, we have developed and applied the tea heat tube. Sulfur heat pipe is under development (water is commonly used as working fluid). Another way is to apply conventional super-heater (Figure 3). |

|

| |

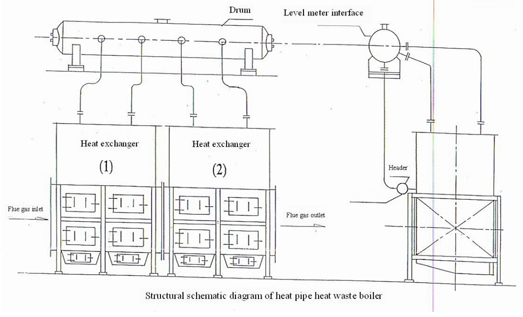

4. Layout of heat pipe waste heat boiler

Two types of heat pipe waste heat boiler layout we mostly use are: one is with dry drum shown in Figure 4a; the other is without dry drum, but equipped with external separation drum shown in Figure 4b |

|

5. Enhancement of heat transfer in heat pipe waste heat boiler

One of the characteristics of heat pipe waste heat boiler is that heat transfer process is enhanced to make the structure compact; ways of heat transfer enhancement is to:

- Increase heat transfer area;

- Increase heat transfer coefficient;

- Improve heat transfer difference.

|

|

Figure 5a shows heat transfer temperature differences of heat pipe waste heat boiler; Figure 5b shows heat transfer temperature differences of boiler with pre-heating section (economizer).

Heat transferring temperature is increased because of the separate pre-heating section. Please refer to Figure 6 for detailed layout. |

|

|

6. Application of heat pipe waste heat boiler

We developed a series of heat pipe waste heat boilers. Several are in operation. Here are five cases.

|

| 6-1: The first case is heat pipe waste heat boiler of Tai Yuan Glass Plant. Its parameters are as follows: |

| |

- Boiler evaporation 3000kg/h

- Steam temp 164℃

- Boiler Design Pressure 0.7 MPa

- Feed water temp 60℃

- Inlet flue gas temp 450℃

- Inlet flue gas capacity 23300 Nm3/h

- Heat pipe 873 pcs

- Length of the pipe 2870 mm

- Resistance of flue gas side 785Pa

|

|

6-2: The second case is heat pipe waste heat boiler of Guangdong Jiangmen Glass Plant. Its parameters are as follows: |

| |

- Boiler evaporation 700kg/h

- Steam temp 169.6℃

- Boiler Design Pressure 0.686 MPa

- Feed water temp 20℃

- Inlet flue gas temp 350℃

- Inlet flue gas capacity 12500 Nm3/h

- Heat pipe 574 pcs

- Length of the pipe 2780 mm

- Resistance of flue gas side 392 Pa (with by-pass flue gas duct for ash cleaning)

|

|

6-3: The third case is heat pipe waste heat boiler of Shanghai No. 2 Steel Works. Its parameters are as follows: |

| |

- Boiler evaporation 2000kg/h

- Steam temp 164.2℃

- Boiler Design Pressure 0.59 MPa

- Feed water temp 20℃

- Inlet flue gas temp 350℃

- Inlet flue gas capacity 30000 m3/h

- Heat pipe 367 pcs

- Length of the pipe 3836 mm

- Resistance of flue gas side 83.8 Pa

|

|

6-4: The fourth case is heat pipe waste heat boiler of Guangdong Zhaoqing Glass Plant. Its parameters are as follows: |

| |

- Boiler evaporation 700kg/h

- Steam temp 138℃

- Boiler Design Pressure 0.55 MPa

- Feed water temp 20℃

- Inlet flue gas temp 350℃

- Inlet flue gas capacity 10066 Nm3/h

- Heat pipe 290 pcs

- Length of the pipe 2570 mm

- Resistance of flue gas side < 491 Pa

|

|

6-5: The fifth case is heat pipe waste heat boiler of Nippon Sheet Glass Cooperation. Its parameters are as follows: |

| |

- Boiler evaporation 3000kg/h

- Steam temp 183.2℃

- Boiler Design Pressure 1.0 MPa

- Feed water temp 60℃

- Inlet flue gas temp 450℃

- Inlet flue gas capacity 24527 Nm3/h

- Heat pipe 714 pcs

- Length of the pipe 2870 mm

- Resistance of flue gas side 895.5Pa

|

|

|