Flue gas treatment:

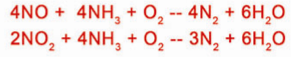

Flue gas treatment to remove NOx is useful in cases in which higher removal efficiencies are required that could not be achieved with combustion control. Selective Catalytic Reduction (SCR) is the most advanced and effective method for reducing NOx emmissions. In selective catalytic reduction, the NOx species are reduced by NH3, ultimately to N2 gas. The predominant reactions are Ammonia being vaporized and injected down steam from the boiler feed water preheater as shown in the illustration at right.

|

|

| SOx Solution |

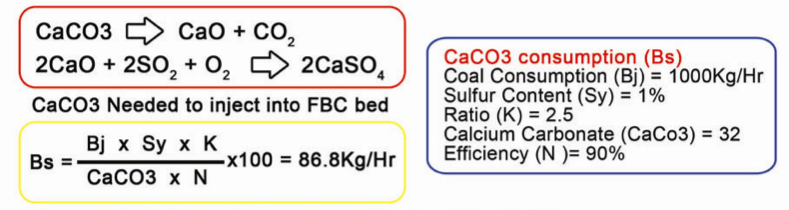

| Option I : Desulfurization at FBC furnace By injection of CaCO3 |

|

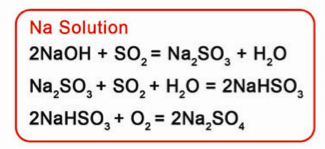

| Option II : Desulfurization at the Venturi Scrubber by mixing NaOH |

|

For DF Series, most of the case, we use Multi Cyclone and Venturi Wet Scrubber only, without employment of expensive DeSOx tower. Specially if you use Indonesian coal of below 1% sulfur content, SO2 level is lower than the government set value. You have two (2) options to remove SO2 according to the content. First OPTION is to inject CaCO3 into the Furnace. Second OPTION is NaOH solution to be injected to the Venturi Water Scrubber for reaction as indicated in this paper. In anyway, FBC boiler does not require expensive DeSOx tower at the exhaust gas area. This is a remarkable advantage of FBC system. |

|

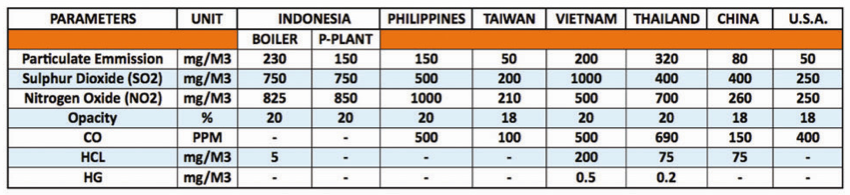

| Emission Regulation - ASIA & U.S.A |

|