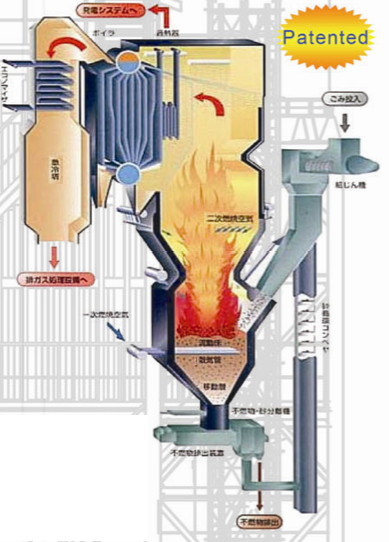

CIRCULATING SAND BED CLEANER:

This system was primarily designed in order to burn fossil fuels with lots of inherent impurities like soil, sand stone, etc., which could not be burned. With its system, the impurities can be removed from the furnace WITHOUT SHUTTING DOWN THE BOILER and thus, it could be operated ON-LINE. When the sand bed have already substantial amount of impurities on it, it can be noticed from the furnace pressure indicator from the control panel. It has a HIGH, NORMAL and LOW level. When the indicator shows HIGH level, the operator will open the shutter below the sand belly and the sand with lots of impurities was drained to the oscillating sand screen cleaner where the impurities goes down to the dirt bin, while the clean sand goes back again to the furnace by means of a pneumatic conveyor/blower. This could be done WITHOUT SHUTTING DOWN THE BOILER. It only takes about 10 - 15 minutes every cleaning time, and the sequence depends on the purity and/or dirtiness of the coal. Based on experience, 2 - 3 times cleaning of the sand has been observed every 24 hours of operation.

|

|