page 53

| HAMADA BOILER WEB CATALOGUE |

| Wuxi fosterwheeler |

page 55

page 53 |

|

page 55 |

WUXI-Hamada CFBC & Foster Wheeler USA |

WUXI BOILER Works is one of the BIG utility boiler manufacturers in China. From the beginning of 1970's, it started developing and researching fluidized bed combustion technology. Based on experience of almost 20 years, WUXI BOILER has successfully developed bubbling fluidized bed boilers with capacity 20, 30, 65; circulating fluidized bed boilers (CFB) with capacities of 20, 65 Ton/ hr. and up to 220 Ton/ hr. To meet the demand of larger CFB in electricity industry, WUXI BOILER signed the License Agreement on Circulating Fluidized Bed Boilers with Beijin Bobcock & Wilcock who has the License agreement with Foster Wheeler Corporation (FW) of the United States on March 10 1994, and introduced advanced design, manufacture, commisioning and control technology. FW finished technical training of WUXI's 24 engineers in September, 1995. |

|

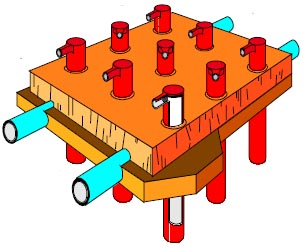

Water cooled plenum are extention of furnace front and rear walls. The furnace shares side walls with the plenum. |

Features of WUXIFW Fluidized Bed Boiler : With the two companies combining their latest technology in combustion engineering, WUXI-FW Fluidized Bed Boilers assures you "combustion efficiency" as high as 98-99%, "Polluiton free" because of its low emission of poisonous matter meeting stringent environment regulations in all countries. It has good fuel adaptability (palm wastes, coal, wood sawdust, baggase, rice hull, oil sludge/shale, etc.) . It maintains above minimum combustion temperature with low staem load (minimum 20-30% load without oil supoort). The furnace operating temperature of WUXI-FW FBC boilers are usually between 850-900 oC. In the lower furnace, there is a dense-phase bed of a few feet height. Above the dense bed, there is a free-board zone which is relative lower dense. The unique features of WUXI-FW FBC boilers is that materials can fluidized well using coarser fuel and desulfurizer particles at relatively low primary air velocity. In addition to these WUXI-FW FBC boilers have other special design features such as : |

|

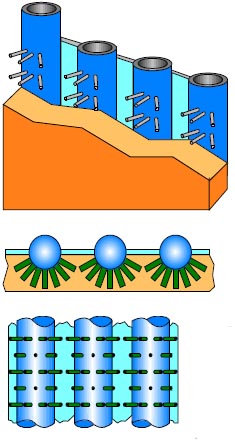

Directional Air Nozzle : |

1. Water-cooled air plenum and watercooled air distributor with directrional air nozzles :

2. Air Swept Feeder system : Very unique Palm Fiber feeding mechanism has been developed using pressureized air swept system. Palm fiber waste is supplied form the front wall. System is designed to prevent clogging of fiber and to assure the smooth and evenly flow of fiber into the furnace at all times. Fuels are sent by a draglink conveyor, which is simple and easy for maintenhance with low speed. At the end of conveyor feeder, a vertical chute with expansion joints and a guillotine damper is installed. The fuel feed compressor behind the air heater supplies high pressured hot air at every angles of the chute with expansion joints and a guillotine damper is installed. The fuel feed compressor behind the air heater supplies high pressured hot air at every angles of the chute to spread fiber. This system can effectively prevents back fire of hot gas from the furnace. |

|

Refractory Cover : 1/2 thick typical refractory covering the staggered elevations water tube. |

3. High Efficiency Membrane Wall Furnace No Bricks Needed : Membrane wall design, which permits standard insulation and lagging greatly reducing radiation losses as compared to the conventional tube arrangement with thick refractory wall. It reduces weight and reduces space requiremetns; Economical fabrication ith conventional manufacturing techniques, including shop-installed refractory are the great features of WUXI FW models.Speciall designed water cooled plenum and water cooled distributor with directional nozzles to improve combustion efficiency, discharged foreign materials, prevent slagging on the air distributor, fully burn the uncombusted carbon in the spent bed material and much more |

page 53 |

Download This |

page 55 |