page 12

| HAMADA BOILER WEB CATALOGUE |

| Fbc 1 |

page 14

page 12 |

|

page 14 |

FLUIDIZED BED SYSTEM |

|

|

|

|

FLUDIZED BED SYSTEM: Indonesian furnace, some problem is expected as a result of melting ash. Semi-Bituminus coal, when fired with the conventional In order to solve "Fluidized Bed System". such problems, we introduce which uses fluidizing “Silica Sand” in order to catch the flying away unburned gas, to give enough time for complete combustion, to distribute heat evenly throughout the combustion area, to enable installation of water tube assembly emerged inside the sand bed to transfer heat from the fluidizing fire to lower the sand bed temperature below 1,000 oC, and to allow injection of Limestone to react with the harmful SO2 gas. Left picture shows the arrangement of submerged water tube installed inside the sand bed. Because of this tube, bed temperature can maintain at below 1000 oC below the ash melting point. Only the Fluidized Bed System can do this for the total solution of melting ash problem which has been giving mile-stone problem to other combustion method. Moreover, the heat transfer efficiency of the submerged tubes is 5-6 times higher than the co-efficient of heat transfer of the conventional boiler convection tubes. Almost 30% of the total steam output can be generated from this submerged tube banks because of this. |

|

|

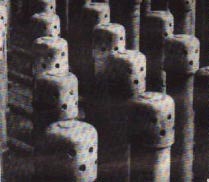

Air-distributor: Left picture is the view of multiple air-nozzles installed at the bottom of the FBC furnace below the sand bed. If asked what is the disadvantage of Fluideized Bed after hearing so many advantages over the other systems, my answer is that FBC need big power to lift up silica sand with the high pressure air of about 1000 mmH2O. Motor for FDF may be 2 times bigger than the motor used for the other system. It is, however, such disadvantages can easily be compensated by higher combustion efficiency that will give more benefit to the user. A big hole shown in the left picture is the sand discharge valve where some big pieces of sludges will also fall to be discharged periodically. |

|

FBC fire/ looks like lava of volcano: Inside of lava coming from volcano, nothing remains unburned. Fluidizing fire is the same status. No unburned carbon. For sulfur problem, CaCO3 may be injected for reaction with SO2 to become CaSO4 which is unharmful. Such injection is not possible for other systems. Nox problem is also not applicable for Fluidized Bed’s low temperature combustion below 1000 oC. This is why most of the latest power plant in the leading countries adopt Fluidized Bed for it’s advantage in pollution control as environmental protection is the main issue to be solved in every big coal firing plant. |

page 12 |

Download This |

page 14 |